Industrial Agility

Transforming for the Digital Age

In light of the fourth industrial revolution and the Internet of Things, Sulzer is reinventing its business for the future. We are making use of additive manufacturing technologies and digital tools. In this way, we make our customers and ourselves faster, better, and more agile.

Transforming has been important at every step of history. Businesses have always changed and adapted to new realities. However, today’s technologies have accelerated the pace of development and intensified the extent to which companies have to change their processes and even business models.

We are transforming for the benefit of our customers. How do we do that? It all comes down to what we call industrial agility. We connect our businesses, we make our products smart, we increase productivity, and we drive growth.

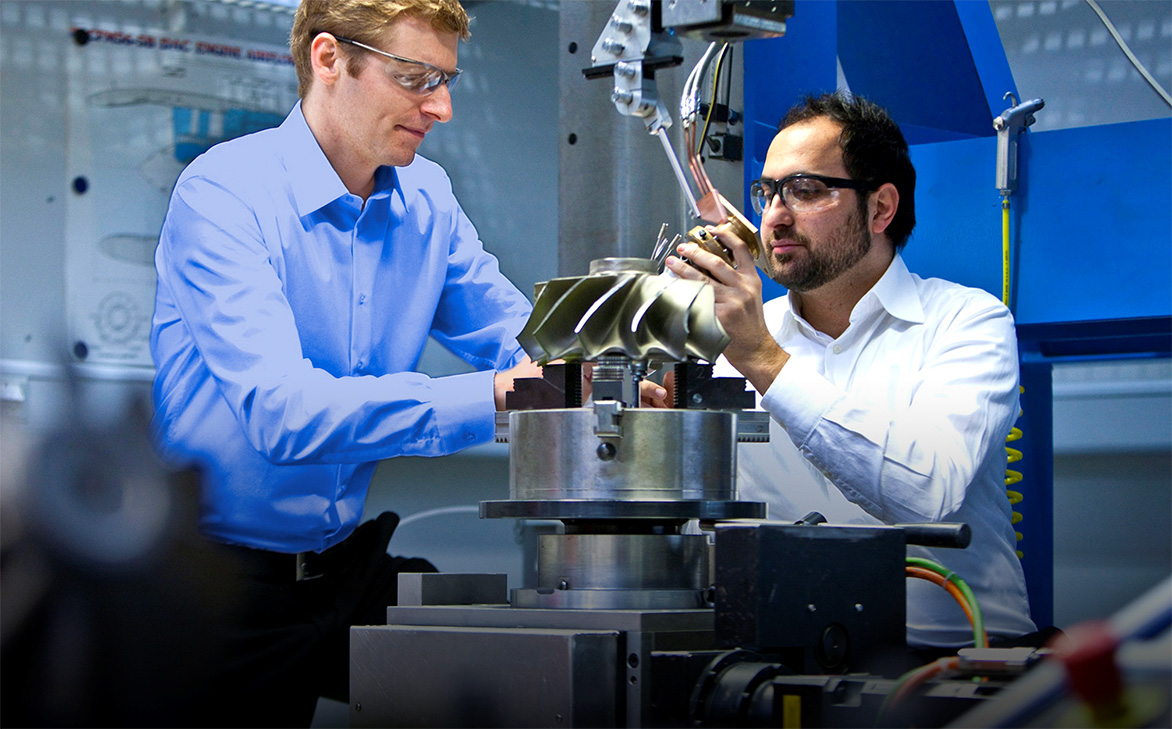

Sulzer keeps testing new manufacturing technologies such as additive manufacturing to meet the highest quality standards and reduce delivery time. In additive manufacturing, also known as 3D printing, layers of material are formed one by one under computer control to create a three-dimensional object. Compared with conventional manufacturing, 3D printing creates little-to-no material losses. As the complexity of a design shape increases, using additive manufacturing saves costs and creates new design freedom.

In today’s world, we are all connected to each other. Likewise, we are connecting our products and factories. They are communicating, and we are listening. We are turning your pumps into smart devices. We are developing a sensor that can measure the temperature and vibration of your process pumps in the field and transfer this information wirelessly to you. Further, we have reorganized and digitally enabled our global pumps manufacturing and supply chain network. The future factories will be smart and learning constantly. In this way, we will be able to cut delivery times and offer our customers competitive prices at the same time.

Letter to the shareholders

Markets are changing faster than ever before. Technology has upended the oil and gas landscape, taking the USA in a few years from the status of net importer to surpassing Saudi Arabia as an oil producing nation. It has made data, ours and our customers’, the most valuable commodity of all. It has allowed us to enter new markets, but has also empowered a new breed of competitors in domains where significant industrial assets used to be a prerequisite to compete. And it makes the world a global village, creating limitless opportunities for efficient collaboration across our company and beyond.

Our highlights

Find out more

Contribution from acquisitions on order intake in 2017

We launched the first group-wide Sulzer Innovation Awards in 2017

We donated 4 modular units to a South African non-profit organization