Pack it up – collapsible cartridges reduce waste and cost

Working with adhesives causes waste. Sulzer’s Applicator Systems division has developed a packaging system that not only reduces waste but also reduces total system cost for customers. Introducing: the ecopaCC™ collapsible cartridge.

Adhesives, an invisible fastening technology, surround us everywhere in our daily lives. It is a technology used in many different industries. Adhesives provide various benefits – such as sealing and bonding of all kinds of substrates – that mechanical fastening systems do not offer. Adhesives are used in civil construction, for windshield bonding in your car and for bathroom sealing applications in your home, amongst many other uses.

Innovative solutions for waste reduction needed

Adhesives dispensed by cartridge-based packaging systems generate waste. The disposal process for residual material, transportation and storage contribute to higher costs.

National and international regulation increases on a daily basis. For example, the state of California in the US has introduced penalties for excessive use of rigid plastic packaging. The EU is about to release a new regulation to avoid plastic waste. The Japanese government has also started discussions to tackle the problem of plastic waste.

Next-generation functional packaging

Conscious of the ecological challenges to come, Sulzer’s Applicator Systems division engineered a next-generation primary packaging for adhesives applications: the ecopaCC™ collapsible cartridge. The cartridge, which uses high-tech multilayer foils suitable for various chemicals, is collapsible and provides customers with savings across the entire value chain.

With our eco-friendly alternative to conventional packaging, customers reduce their costs across the value chain.

Amaury de Menthiere, Division President Applicator Systems

Conventional cartridge systems are disposed of once emptied. With the ecopaCC™, the only waste that remains is the collapsed foil and the small front part. Both take very little space. Moreover, the support sleeve for the cartridge is reusable and thus an important factor behind the ecological concept.

Additive manufacturing speeds up prototyping

When new products are launched, we want to deliver solutions to customers as quickly as possible. Additive manufacturing of smaller-volume components allows us to speed up the early stages of development before an expensive manufacturing tool has been built.

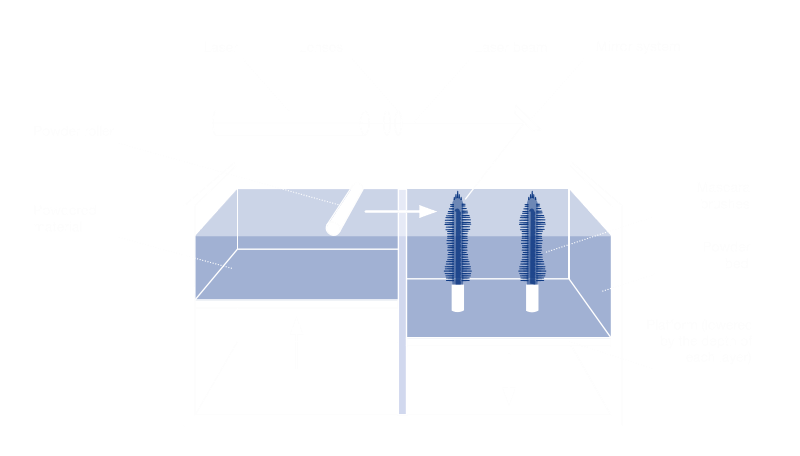

Thanks to additive manufacturing, Sulzer has considerably accelerated the development process and hence time to market of mascara brushes. We can deliver a prototype to customers within one week instead of 18 weeks. Thanks to a new material applied through selective laser sintering (an additive manufacturing technology) the bristles are stable enough to separate the eyelashes yet elastic enough not to hurt the eyes. In this way, the customer can actually test the prototypes effectively.

Functional principle of the selective laser sintering process, also called SLS.

Significant cost reduction

Overall, customers can achieve significant savings by using ecopaCC™. For example, the transportation and storage cost of the empty, pre-collapsed 600 ml cartridge can be reduced by up to 85%, since seven times more cartridges can be packed onto a euro pallet. Additionally, once the cartridge reaches the end of its lifetime, waste disposal will cost our customer 75% less.

The new packaging system is designed to fulfill the highest quality expectations. The molding technology allows for a 100% leak-proof connection between the foil and front-end part. The system is compatible with our dedicated dispenser range as well as the static mixers.

Eco-friendly and ready to be certified

Sulzer has applied for the renowned EU Ecolabel for its new product. With more than 54’000 products and services on the market, the EU Ecolabel is well recognized. It is a very reliable and effective way to show consumers that a product or a service is both eco-friendly and of supreme quality.

The EU Ecolabel also opens up new business opportunities. B2B companies are facing increasing pressure to work with manufacturers of products that bear ecolabels in accordance to ISO standards in order to fulfill high-level supply chain requirements by customers.

More stories about our products and services at www.sulzer.com/stories.